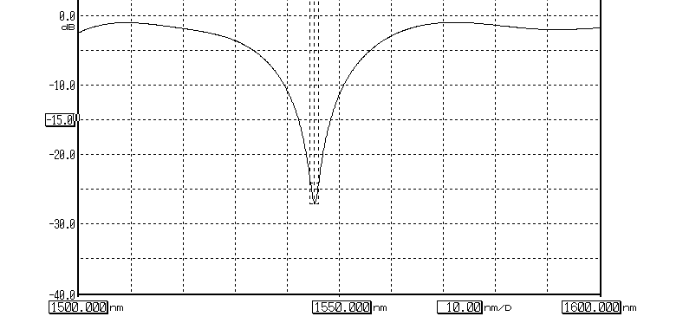

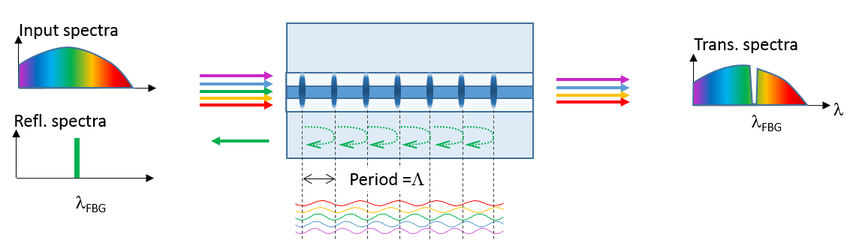

Under the effect of photoinduction, a grating effect was generated in the germanium-doped fiber. In 1978, researchers accidentally discovered this phenomenon during an experiment, and the world's first fiber optic grating was successfully produced. A large number of researchers began to delve into the basic principles, production methods, and practical applications of fiber optic gratings, and conducted a lot of technological improvements and refinements. Quartz is the main material that makes up fiber optic, consisting of a core and a cladding layer. The outer layer is protected by a coating layer. There are many types of fiber optic gratings, among which the most typical and earliest developed is the fiber Bragg grating, which is also one of the most widely used fiber optic gratings.

Compared with other traditional sensing devices, fiber optic grating sensors are mainly based on the characteristics of fiber optic transmission. They originated from fiber optic communication technology and have been widely used through years of exploration, practice, and application research. For example, they are frequently used in petroleum and chemical industry, electronic information, geological exploration, and civil engineering and bridge detection. The structure of the fiber in the fiber optic sensor is very similar to that of ordinary communication, divided into three parts: core, cladding, and coating.

The fiber optic core is mainly composed of silica and specific light waves are transmitted in the core based on the physical principle of total internal reflection. Due to the photo-sensitive nature of the core, the refractive index of the fiber changes according to different light sources. Therefore, measurements of temperature, humidity, deformation, and tension changes can be accurately measured through the wavelength changes in fiber optic gratings. The fiber optic grating sensor structure is very simple and can achieve a small size. It is also characterized by high reliability, high accuracy, strong waterproof performance, and high sensitivity. Compared to other types of sensing devices, fiber optic grating sensors have good stability, high reliability, are less affected by external environmental factors, and are easy to build sensing networks. They can be placed at multiple locations within a building for independent real-time monitoring of multiple parameters, fully demonstrating their capabilities in complex building structures.

Currently, China requires that fire safety warning information application systems be equipped in areas such as oil exploration, power facilities, tunnels, bridges, and rail transportation. As a new generation of sensing technology, fiber optic grating technology has the characteristics of high reliability, high accuracy, strong waterproof performance, high sensitivity, less affected by external environmental factors, and easy to build sensing networks. In addition, fiber optic grating sensing technology has a broader application field and greater potential. It has quickly established a foundation for application in these industries, and the application of fiber optic grating sensing technology is rapidly developing.

With the constant improvement of modern science and technology, new technologies, processes, and achievements in the application of fiber optic grating sensors will further emerge in the future. Fiber optic grating sensors will be applied and promoted in more fields, replacing traditional sensors. The market share of fiber optic grating sensors in many fields such as civil engineering, health care, petroleum exploration, power electrical equipment, electronic information, and biomedicine will further increase significantly, and the corresponding technological achievements transformation will be further accelerated.