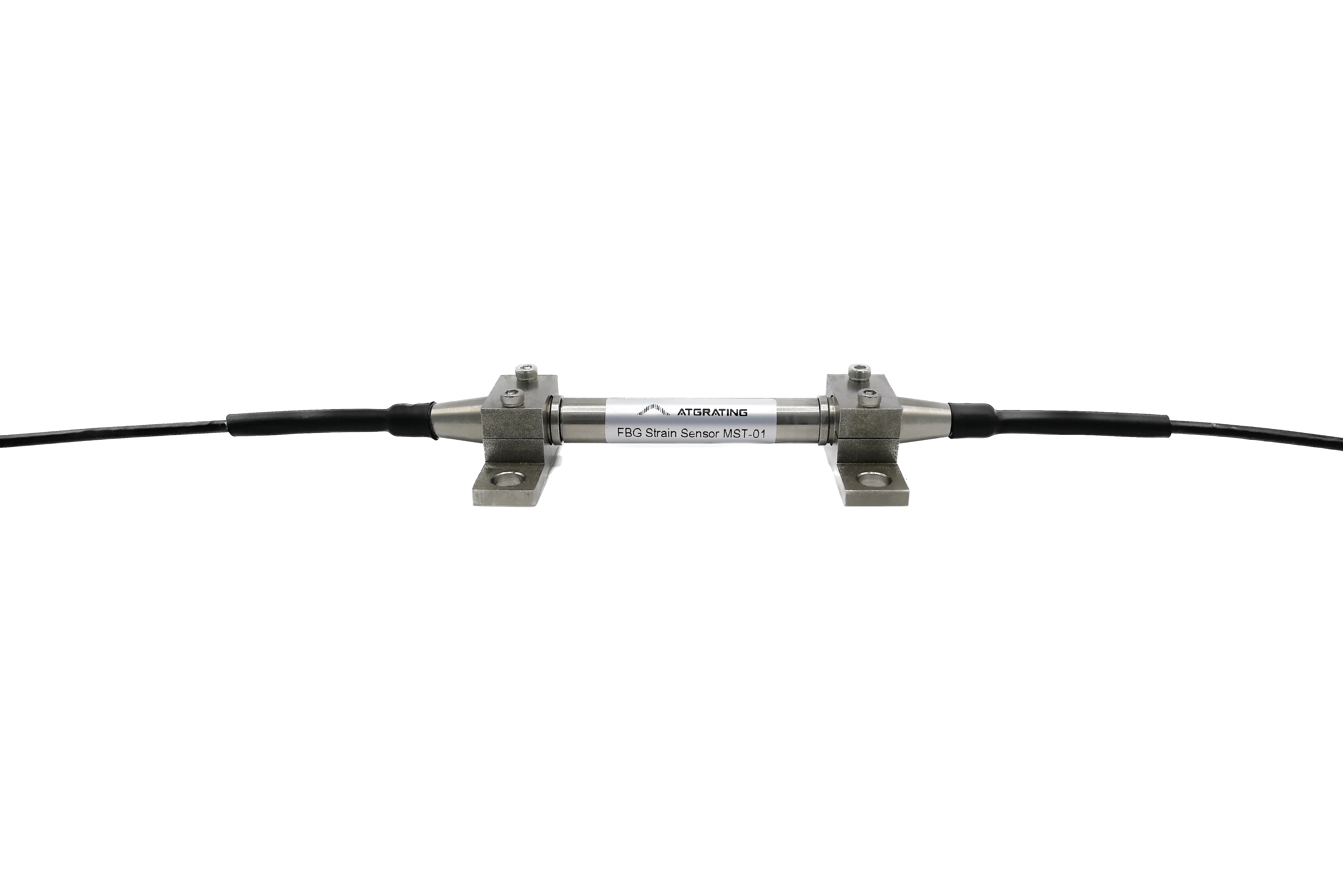

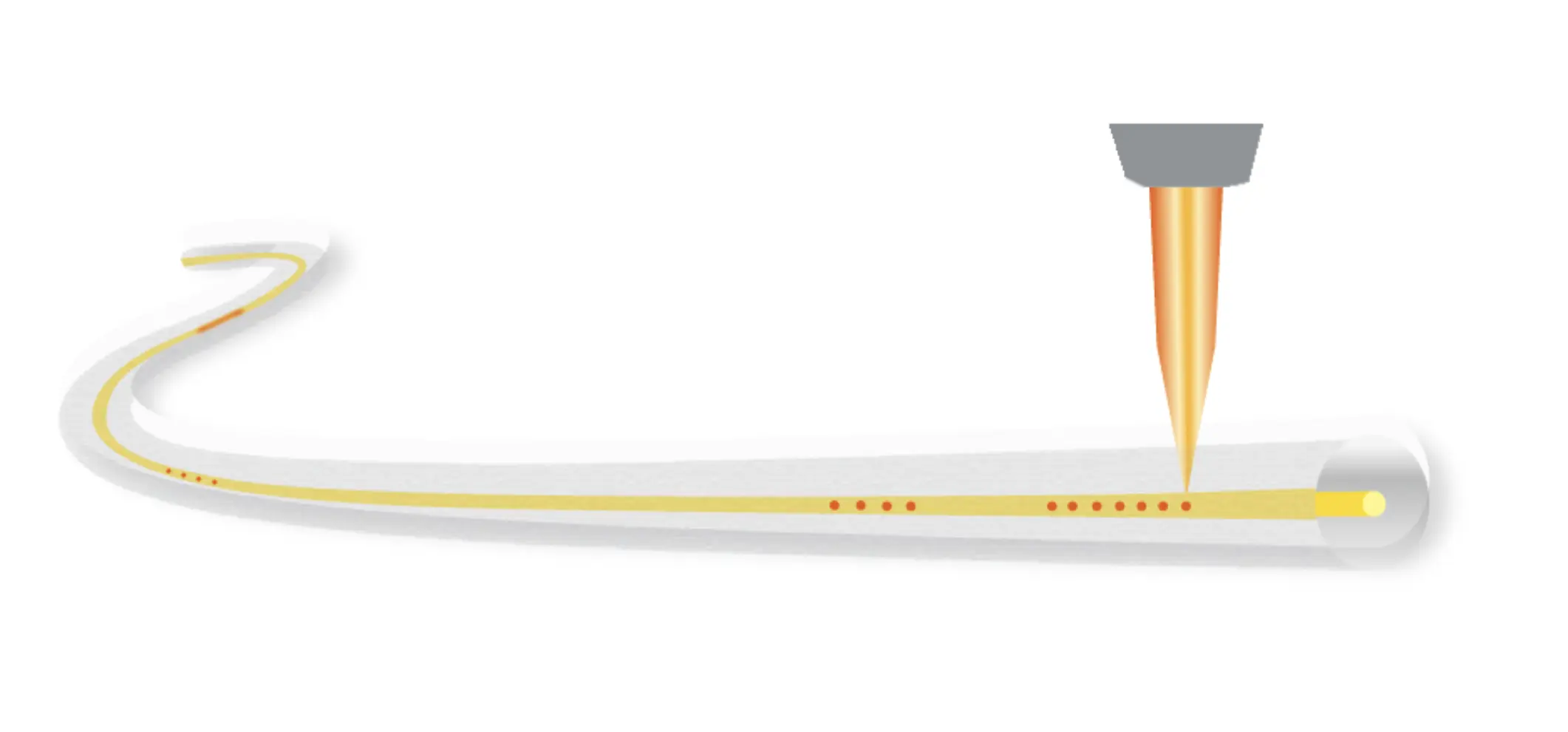

Fiber grating sensors are not interfered by electromagnetic fields and can achieve long-distance low-loss transmission, making them an ideal choice for power industry applications. The load capacity of the wire, the temperature of the transformer winding, the large current, etc. can all be measured by the fiber grating sensor.

In the electric power industry, current converters can convert current changes into voltage changes. Voltage changes can cause piezoelectric ceramics (PZT) to deform. Using the wavelength shift of the fiber grating attached to the PZT, it is easy to know its deformation. Then measure the current intensity. This is a relatively inexpensive method and does not require complex electrical isolation. In addition, excessive pressure applied to the wires by heavy snow may cause dangerous events. Therefore, it is very important to detect the wire pressure online, especially for those mountainous wires that are not easy to detect. The fiber grating sensor can measure the load of the wire. The principle is to convert the change of the load into the change of the stress on the metal plate close to the wire. This stress change can be detected by the fiber grating sensor glued to the metal plate. . This is an example of using fiber grating sensors to achieve long-distance measurement in harsh environments. In this case, the distance between adjacent gratings is relatively large, so fast modulation and demodulation are not required.

Latest News at ArGrating FBG Sensing

_1200_x_628_Banner.webp)

2025-Apr-16

+

2024-Oct-01

+

2024-Sep-17

+

2024-Sep-01

+