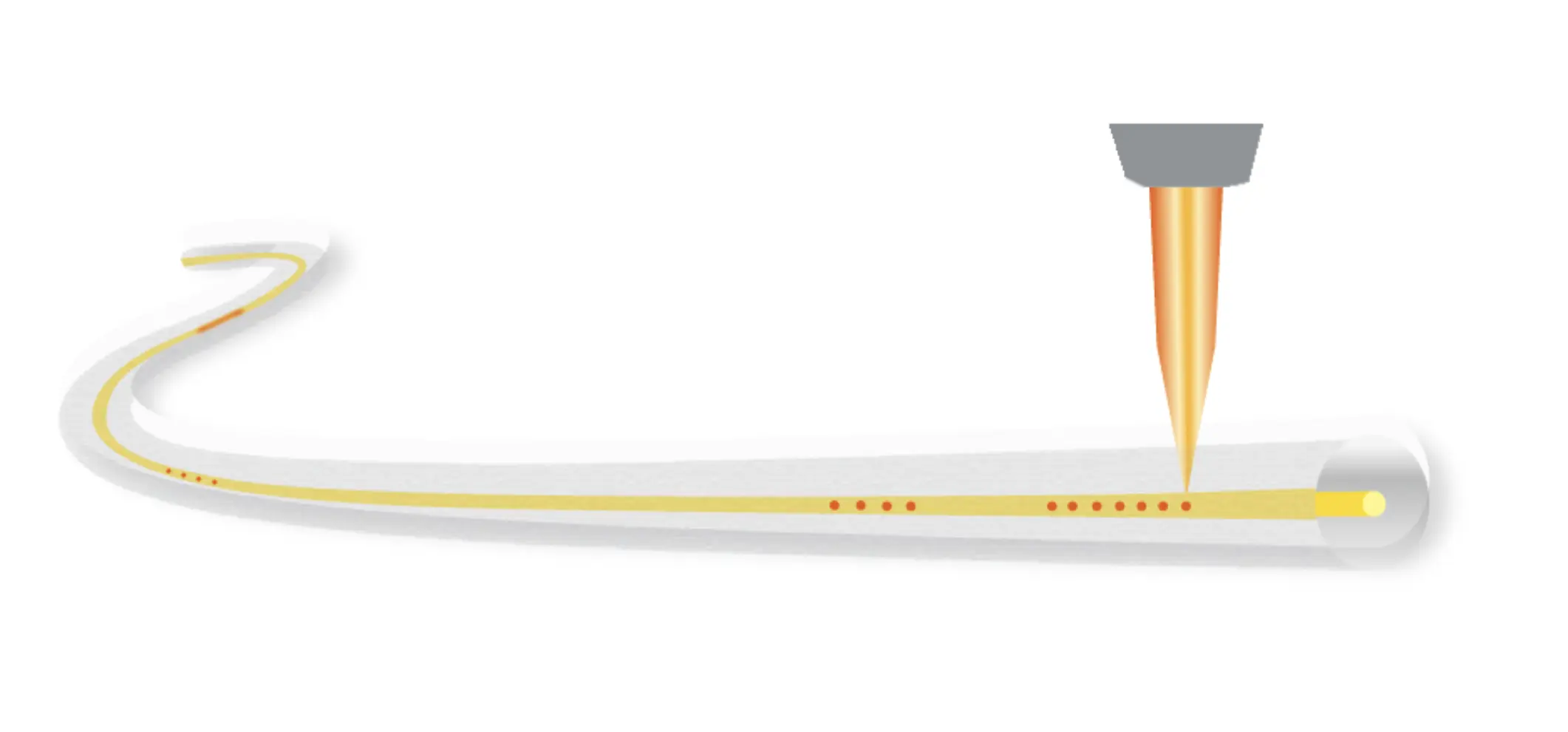

The armored cable is a cable with ultra-sensitivity used for quick and easy strain monitoring in secure projects for periphery intrusion warning systems.

An array of FBG sensors composes the core of the cable. The interlayer of the cable is a PE, PU or Polytef coating to protect the sensor and cable structure.

The cable is used to accelerate and simplify processing and figuration intuitively which offers the numerous benefits inherent in every FBG sensor, while improving ruggedness to meet, if not exceed, industry expectations.

The cable specifications listed here are the most common configurations. There are significant variations in cable structure during the manufacturing, including sensors of other wavelengths, terminations of other types of optical connectors, as well as cable availability of custom lengths and customer-defined spacing between sensing points.

High Sensitivity

Ruggedized

Easy Handling and Deployment

Long Cable Distance

Perimeter Monitoring

Building Security

Energy

Civil Engineering

Parameters | Unit | Values |

Center Wavelength | nm | 1460 ~ 1610 |

Wavelength Tolerance | nm | +/-0.5 |

Strain Sensing Sensitivity | pm/g | 8 |

FBG Length | mm | 5~10 |

Reflectivity | % | 10~90 |

Reflection FWHM | nm | 0.2~0.3, other |

SLSR | dB | ≥15 |

Inner-Cable Fiber Type | -- | SMF-28 |

Mid-Layer Cable Extrusion Material | -- | PE, PU, or Teflon with up to 1.5mm OD |

Outer-Cable Diameter | mm | 3, 4, 5, other |

Pull Strength | kpsi | >100 |

Temperature Compensation | -- | Yes, with various options |

Optical Connector | -- | FC/APC, FC/UPS, other |

Latest News at ArGrating FBG Sensing

_1200_x_628_Banner.webp)

2025-Apr-16

+

2024-Oct-01

+

2024-Sep-17

+

2024-Sep-01

+