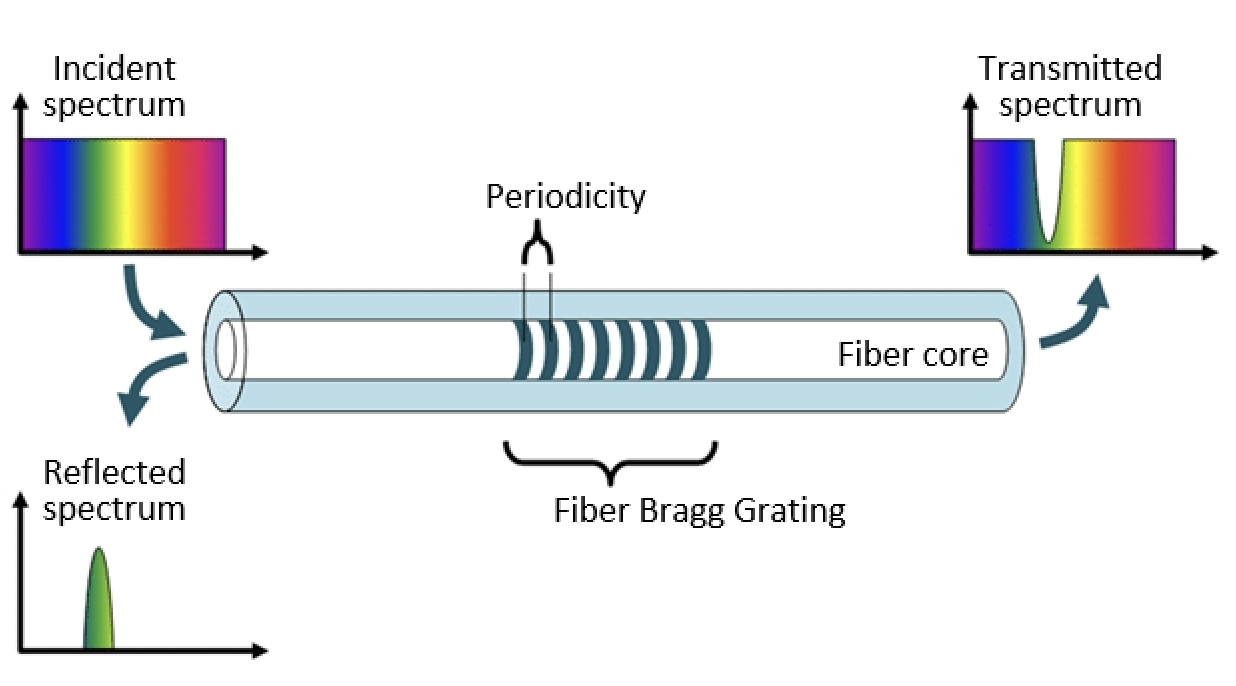

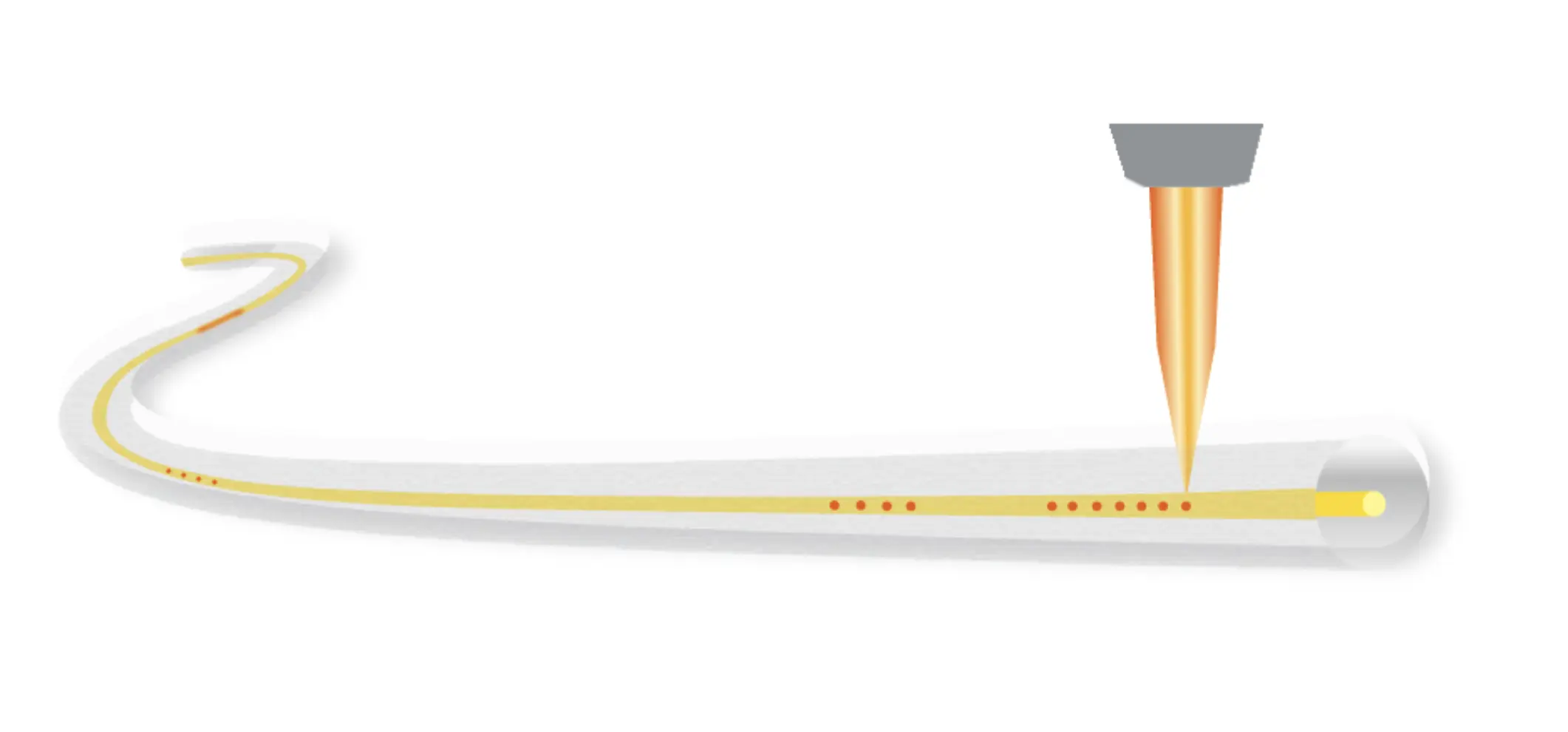

Femtosecond FBG is optical fiber with periodic changes in the core refractive index made by Femtosecond laser direct inscribing without stripping the fiber coating. It is a passive filter that can measure temperature, strain, stress, vibration, speed, acceleration and other variables in extreme and harsh environments with its excellent high temperature resistance and tensile resistance. It can be customized according to customer required parameters.

Building Structural Health Monitoring

Energy monitoring

Biomedical monitoring

Fiber Bragg Gratings (FBGs) are the key components of all-fiber lasers, and are mainly used as laser feedback cavity mirrors and filters.

At present, FBG is mainly written on the photosensitive fiber by ultraviolet continuous or excimer laser. However, fiber Bragg gratings written by traditional UV lasers have poor thermal stability, easy to be erased under high temperature conditions, require cumbersome fiber Hydrogen loading pretreatment, and is not suitable for high temperature environments.

Femtosecond laser micro-nano processing technology is used in glass, crystal, metal and other materials due to its advantages of no thermal effect, wide range of processing materials, processing accuracy that breaks through the diffraction limit, and the ability to achieve three-dimensional processing in transparent materials. At the same time, fiber bragg grating written by Femtosecond laser technology has also attracted widespread attention.

So, what are the advantages and characteristics of Femtosecond laser written FBG?

Femtosecond laser has extremely narrow pulse width and extremely high peak power, which can be used to process any material, and is also suitable for fiber bragg grating written technology. Femtosecond laser FBG written technology has the following characteristics:

1) The processing technology is simple;

2) There are no restrictions on optical fiber materials;

3) High refractive index modulation;

4) The written FBG has good temperature resistance;

5) The out-of-band loss of the written FBG is small;

6) The position of the grating written in the fiber is flexible and controllable, and the birefringence and mode coupling characteristics of the FBG can be adjusted.

More stable: Quartz FsFBG can be stable at 1000℃ for a long time

More durable: no need to strip fiber coating, and recoating

More flexible: no phase mask, no Hydrogen loading required

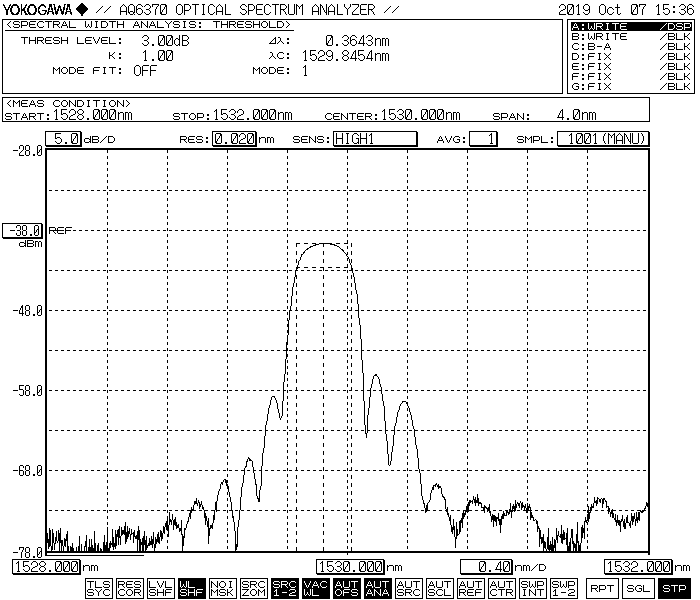

Parameter | Unit | Value |

Center Wavelength | nm | 1460 ~ 1640 |

FBG Profile | -- | Apodized |

Wavelength Tolerance | nm | +/-0.5 |

FBG Length | mm | ≤5 |

Reflectivity | % | ≥50 |

Bandwidth (FWHM) | nm | ≤0.5 |

SLSR | dB | ≥10 |

Tensile Strength | kpsi | ≥100 |

Fiber Type | -- | SM fiber, bend-insensitive fiber, Polyimide fiber, radiation-hardened fiber, Sapphire fiber, etc. |

Pigtail Length | m | Standard 1m both ends, or custom |

Optical Connector | -- | Bare Fiber, FC/APC, SC/APC, or custom |

Operating Temperature | °C | -80 ~ +1000 |

Latest News at ArGrating FBG Sensing

2024-Oct-01

+

2024-Sep-17

+

2024-Sep-01

+

2023-Aug-12

+