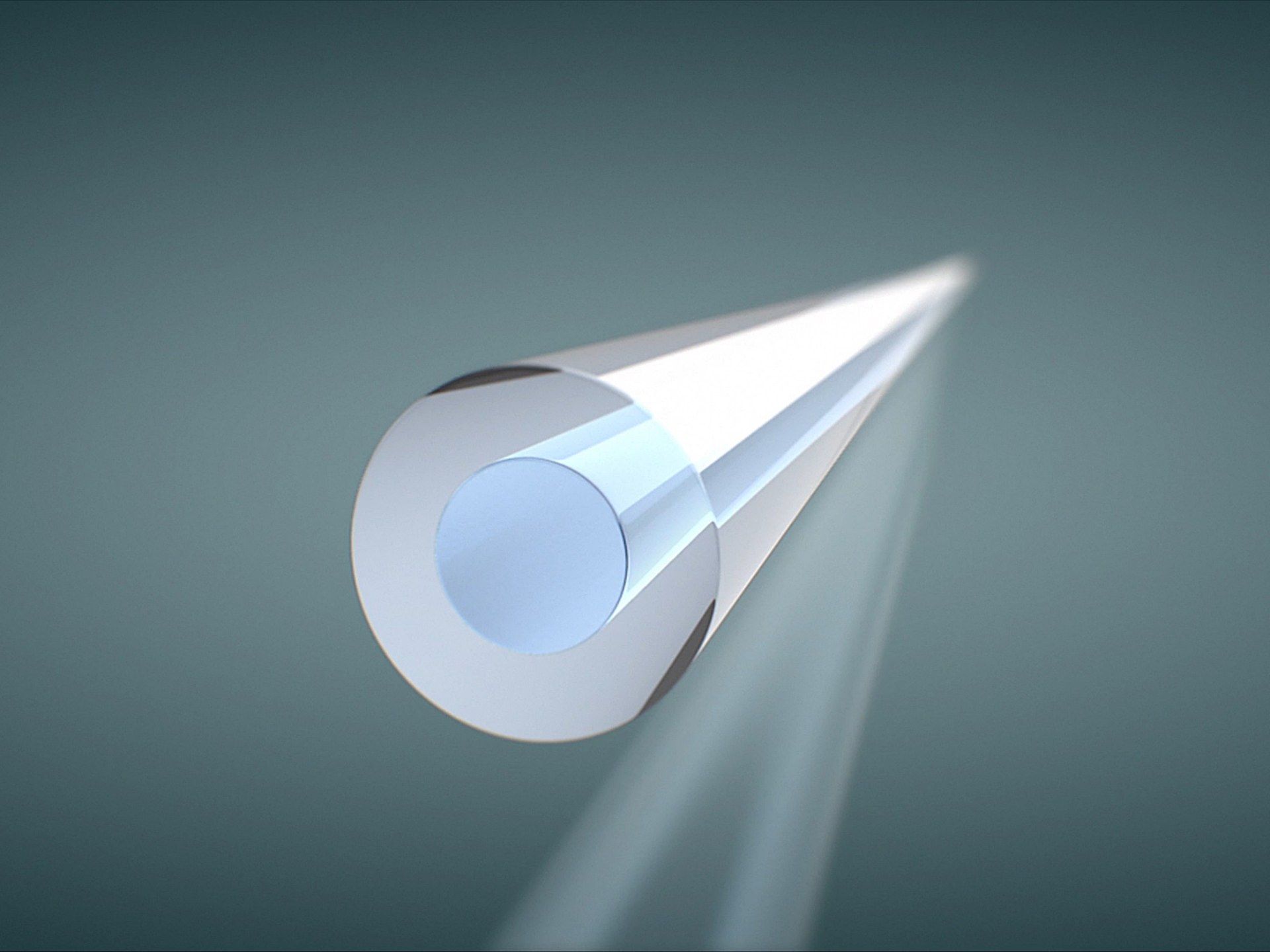

This fiber grating sensor is the most widely used and the most mature fiber optic sensor in the engineering field. Strain directly affects the wavelength shift of the fiber grating. When the working environment is good or the structure to be tested requires a small sensor, people use the bare fiber grating as a strain sensor to directly paste it on the surface of the structure to be tested or embed it inside the structure. Because fiber gratings are fragile and easily damaged in harsh working environments, they need to be packaged before they can be used. At present, the commonly used packaging methods mainly include the substrate type, the tube type and the two-end clamping type based on the tube type.

Temperature is one of the basic physical quantities given by the International System of Units. It is the main parameter that needs to be frequently measured and controlled in industrial and agricultural production and scientific experiments. It is also an important physical quantity closely related to people's daily life. At present, the more commonly used temperature sensors are thermocouple temperature sensors and thermistor temperature sensors. Compared with traditional sensors, fiber optic temperature sensors have many advantages, such as high sensitivity, small size, corrosion resistance, electromagnetic radiation resistance, flexible optical path, and easy telemetry. The temperature sensor based on fiber grating technology adopts wavelength coding technology, which eliminates the influence of light source power fluctuation and system loss, and is suitable for long-term monitoring ; and the temperature sensing system composed of multiple fiber gratings uses one optical cable to achieve quasi-distribution measurement.

Temperature is also a factor that directly affects the wavelength change of fiber gratings, and people often directly apply bare fiber gratings as temperature sensors. Like the fiber grating strain sensor, the FBG sensor also needs to be encapsulated. The main function of the encapsulation technology is to protect and increase sensitivity. People hope that the fiber grating can have strong mechanical strength and also hope that fiber grating sensors have long life. In optical fiber sensing, the response sensitivity of fiber grating to temperature can be improved by appropriate packaging technology.

The researchers have carried out research on the application of fiber grating for displacement measurement. At present, these studies are all by measuring the strain on the surface of the cantilever beam, and then calculating the vertical deformation of the cantilever beam, that is, the vertical displacement of the end of the cantilever beam. This kind of " displacement sensor " is not a displacement sensor in the real meaning, and this kind of sensor has been applied in practical engineering at present.

The monitoring of tension or pressure is also an important part of monitoring, such as the overall cable force of the bridge structure, the ice pressure of the high-latitude ocean platform, and the soil pressure and water pressure of the road. The researchers developed a fiber grating cable pressure ring and a fiber grating ice pressure sensor, and the British Naval Research Center developed a fiber grating soil pressure sensor to monitor the load situation inside the road. And countries have successively started research work on fiber grating sensors for oil and gas wells.