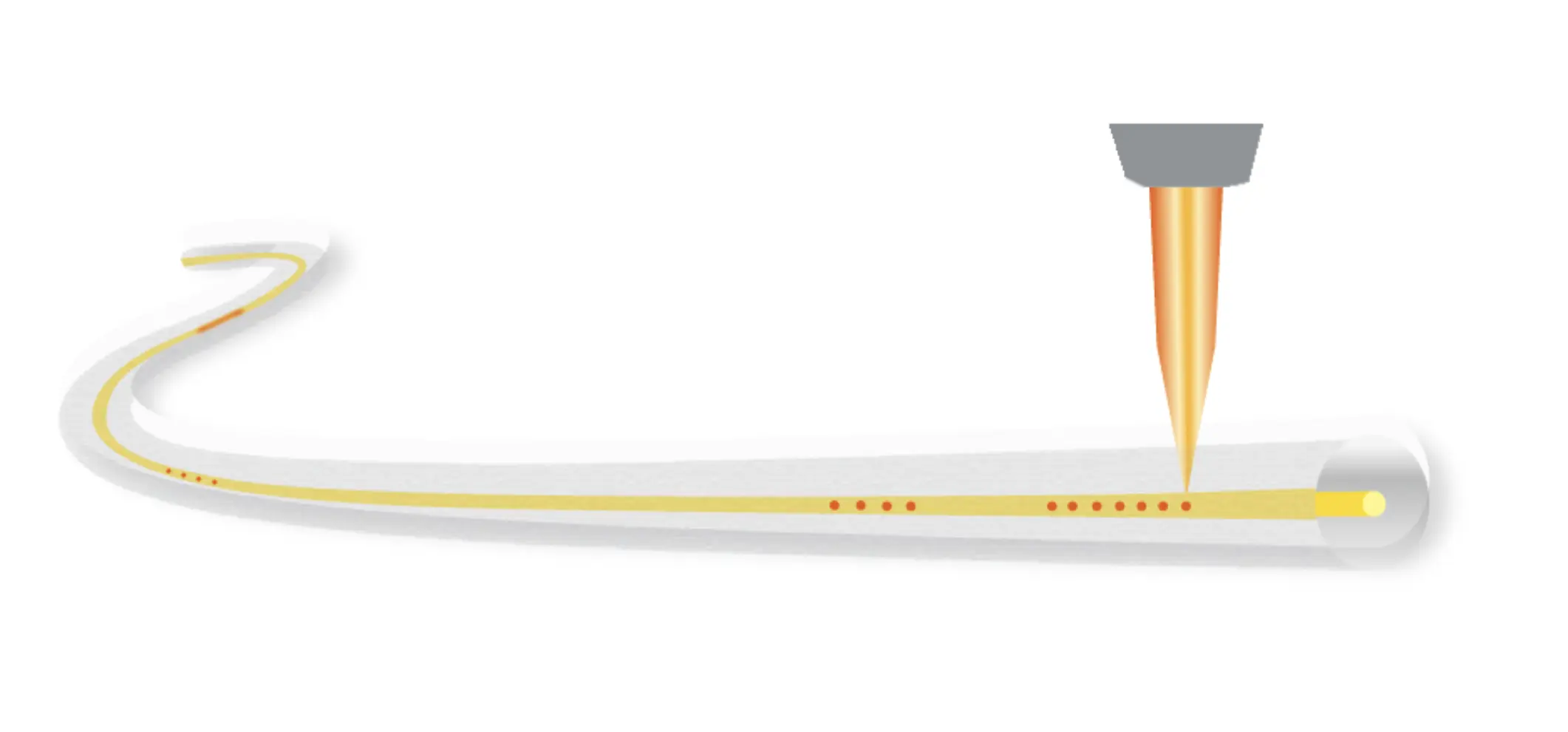

FBG is a core element used as a sensor for structure health monitoring. The tight buffer FBG array consists of FBG array sensors. The outer layer could be material of PVC, nylon or hytrel which protects the FBG sensors and ruggedizes the construction.

The tight buffer FBG array is designed to make handling and installation fast, easy and intuitive. It delivers the many advantages inherent to all FBG based sensors while elevating the degree of ruggedness to be consistent with, if not exceeding, industry expectations.

No Splicing Point

Customer Defined Grating Characteristics and Spacing

High Stability and Reliability

Long Fiber Distance

Distributed Sensing Measurement

Wavelength Reference

Aerospace Engineering

load Monitoring for Power Transmission

Parameters | Unit | Values | |||

Center Wavelength | nm | 1460 ~ 1610 | |||

Wavelength Tolerance | nm | +/-0.5 | |||

FBG Length | mm | 3 | 5 | 10 | 15 |

Reflectivity | -- | ≥70% | ≥75% | ≥90% | ≥90% |

Bandwidth at –3dB | nm | ≤0.7 | ≤0.7 | ≤0.3 | ≤0.3 |

SLSR | dB | ≥15 | |||

Mini. Spacing | mm | 10 | |||

Spacing Accuracy | mm | ≤1 | |||

Recoating | -- | Acrylate Or Polyimide | |||

Proof Test | Kpsi | ≥100 | |||

Fiber Type | -- | SMF-28e Or Polyimide Fiber | |||

Fiber Termination | -- | Bare Fiber, FC/UPC, FC/APC Or E2000 | |||

Pigtail Length | -- | Customized | |||

Operating Temperature | ℃ | SMF-28e Fiber: -40 ~ 120; Polyimide Fiber: -40 ~ 300 | |||

Latest News at ArGrating FBG Sensing

_1200_x_628_Banner.webp)

2025-Apr-16

+

2024-Oct-01

+

2024-Sep-17

+

2024-Sep-01

+