Optical fiber grating is formed on the optical fiber by using the UV sensitivity of the silicon fiber, thus it is called fiber grating. FBG sensor is a type of optical fiber sensor, and its sensing process is based on modulation of Bragg wavelength of optic fiber by external physical parameters to obtain sensing information, which is a wavelength modulation type of optical fiber sensor.

Multiple sensors need to be combined according to a certain network topology, and controlled and coordinated through the same photoelectric terminal, so as to realize the detection, identification and demodulation of multiple sensor signals. Here, fiber Bragg grating sensor and its network technology are taken as a typical example for illustration. The application of fiber Bragg grating sensors to measure physical quantities related to temperature and strain is one of the advanced sensing technologies in the field of monitoring. Currently, cycles are commonly used in structural deformation and temperature monitoring.

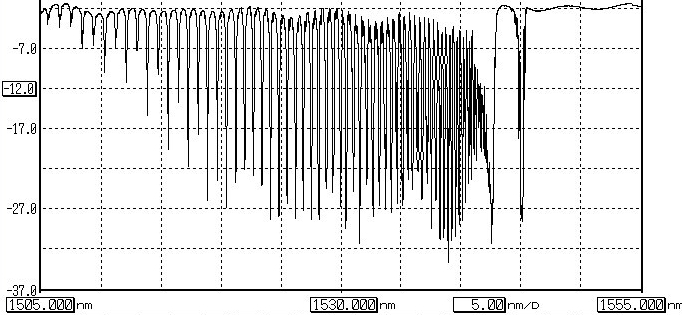

When the continuous broadband light emitted by the light source is transmitted into the optical fiber and selectively reflected back a narrowband light at the grating, the remaining broadband light continues to transmit and reflect at the next grating with different central wavelength. Multiple grating arrays form the fiber Bragg grating (FBG) sensing network. The central wavelength of each FBG reflection is λ=2n, where n is the effective refractive index of the fiber core and is the modulation period of the fiber core refractive index.

There are 3 types of spectra on FBG sensor structure, including incident spectra, reflected spectra, and transmitted spectra. The central wavelength of the reflected narrow-band light changes linearly with the temperature and strain applied to the fiber grating. The change in the central wavelength is Δλ. The reflected central wavelength (short period fiber grating) or transmitted central wavelength (long period fiber grating) of the fiber grating is related to the refractive index of the medium. When the parameters such as temperature, strain, pressure, magnetic field change, the central wavelength will also change. By detecting the change in the central wavelength of the reflected or transmitted spectrum using a spectrometer, the changes in the external environmental parameters can be indirectly detected, and its change is correlated with the strain and temperature changes.

Based on the FBG sensing network analysis instrument, each FBG sensor can be addressed in the reflected light. By utilizing the reference light information and the change amount, the measured temperature and strain values can be demodulated. By attaching FBG to mechanical structures with determined material properties and geometric sizes, strain-based force sensors, displacement sensors, and vibration sensors can also be made.